(Updated December 13th, 2022)

The past-producing Wind Mountain gold/silver project is located approximately 160km northeast of Reno, Nevada in a sparsely populated region with excellent logistics, including county-maintained road access and a power line to the property. A previous owner, AMAX Gold recovered nearly 300,000 ounces of gold and over 1,700,000 ounces of silver between 1989 and 1999 from two small open pits and a heap-leach operation (based on files obtained from Kinross Gold, successor in interest to AMAX Gold). Rio Fortuna Exploration (U.S.) Inc., a wholly owned US subsidiary of Bravada Gold Corporation, acquired 100% of the property through an earn-in agreement with Agnico-Eagle (USA) Limited, a subsidiary of Agnico-Eagle Mines Limited, which retains a 2% NSR royalty interest, of which 1% may be purchased.

The Company reported in December 2022 the results of an updated, independent Resource and Phase I Preliminary Economic Assessment (PEA) for Wind Mountain.

For a 5-minute drone video on Wind Mountain with President Joe Kizis discussing features of the PEA, click here.

Economics have improved significantly compared to the Company’s 2012 study due to utilizing a near-mine, heap-leach pad site for a portion of the Pit-constrained resource and higher grades for early mining, which were predicted and then verified by drilling during 2021. To add additional mine life, a Phase II pad site has been identified due north of the Phase I site, and although somewhat farther from the currently identified Pit-constrained resource, it is located very close to outcropping mineralization at the North End target area, which has only been tested with minor drilling. Other potential additions to mine life that the Phase I PEA did not consider include mineralization at the South End deposit and historic “waste rock piles” where the Company has identified potentially recoverable gold and silver.

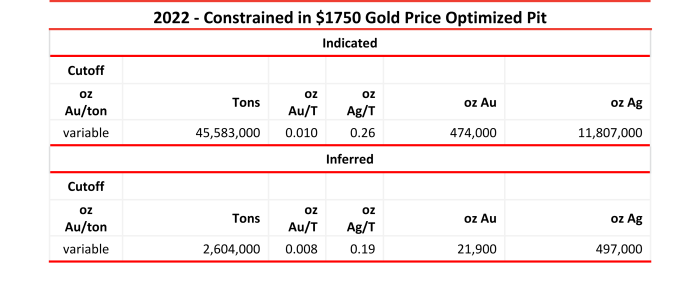

Total Pit-Constrained Resource

After verifying and slightly modifying the Wind Mountain 2012 Global Resource based on subsequent drilling, which was confirmed to within <1%, a total Pit-constrained Resource was calculated by RESPEC Company, LLC (“RESPEC”, formerly Mine Development Associates) utilizing the 3-year trailing-average, base-case price of US$1,750 per ounce of gold and $21 per ounce of silver. Results are tabulated below.

Notes:

- The Effective Date of the Wind Mountain mineral resources is October 4, 2022.

- The estimate of mineral resources was done by RESPEC in Imperial tons.

- Mineral Resources comprised all model blocks at a 0.006oz Au/ton cut-off for Oxide within an optimized pit and 0.014oz Au/ton for Mixed and Unoxidized within an optimized pit.

- The project mineral resources are block-diluted Mineral Resources potentially amenable to open pit mining methods and reported within optimized pits using a gold price of US$1,750/oz, a silver price of US$21/oz and a throughput rate of 20,000 tonnes/day. Assumed metallurgical recoveries for gold are 62% for oxide, 20% for mixed and 15% for unoxidized. Assumed metallurgical recoveries for silver are 15% for oxide and 0% for mixed and unoxidized., Mining costs of US$2.75/tonne mined, heap leach processing costs of US$3.17/tonne processed, general and administrative costs of $0.57/tonne processed. Gold and silver commodity prices were selected based on analysis of the three-year running average.

- Material in waste dumps and heap leach pads are NOT included in the current model and resource.

- Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

- The estimate of mineral resources may be materially affected by geology, environmental, permitting, legal, title, taxation, sociopolitical, marketing, or other relevant issues.

- Rounding may result in apparent discrepancies between tonnes, grade, and contained metal content.

Phase I PEA for a Close-in Heap-leach Site

The Phase I PEA assumes open-pit, contract mining with conventional trucks and shovels and run-of-mine leaching. The base-case economic model(1) is summarized below in US dollars and Imperial units (some values rounded):

Resource inside the pits for Phase I PEA = 29.2 million tons of Indicated Resource @ 0.011 oz Au/t & 0.267 oz Ag/t and 1.08 million tons of Inferred Resource at 0.009 oz Au/t and 0.173 oz Ag/t, both at a cut-off grade of 0.008 oz Au/t. Oxide mineralization = 30.2 million tons and Mixed oxide/sulfide = 0.01 million tons.

Gold & Silver Ounces mined = 344,000 oz Au and 7,975,000 oz Ag.

Gold & Silver Ounces produced = 213,000 oz Au (recovery 61.9%) & 1,194,000 oz Ag (recovery 15%) or 227,000 oz Au-eq(2).

Waste: Ore Strip ratio = 0.55:1

Capital = Initial capital of $46.6 million with $19.8 million sustaining capital

Mine Life = approximately 4.2 years of mining

After-tax Payback Period = 1.8 years

Life-of-mine cash cost(3) = $1,045 per ounce Au

All-in Sustaining Costs = $1,175 per ounce Au

After-tax IRR = 38%

After-tax NVP@5% = $46.1 million

(1) Canadian NI 43-101 guidelines define a PEA as follows: “A preliminary economic assessment is preliminary in nature and it includes inferred mineral resources that are considered too speculative geologically to have the economic considerations applied that would enable them to be classified as mineral reserves, and there is no certainty that the preliminary assessment will be realized. Mineral resources that are not mineral reserves do not have demonstrated economic viability.”

(2) Expected recoveries were incorporated to convert silver to gold equivalent (Au-eq) at 345 Ag:1 Au ($1,750 x 61.9% divided by $21 x 15%)

(3) Costs include estimated Nevada Net Proceeds taxes, property taxes, estimated corporate income tax, and treats silver as a by-product credit

The phased approach to development at Wind Mountain provide for a Phase I that takes advantage of a pad space adjacent to the modelled mining operation. The increased grade verified in the Breeze pit area by drilling during 2021 provides increased cash flow during the early years of production, providing the benefit that cash flow should fund sustaining capital required in year 3. The 2022 Pit-constrained resource would be depleted by about 62% during Phase I and a probable Phase II pad site has been identified north of the Phase I pad. Capital costs to activate Phase II should be reasonable and potentially funded by cash flow. There are several fault blocks of outcropping mineralization based on surface sampling uphill from the Phase II pad that have not been tested by drilling except for results from several encouraging shallow drill holes at North Hill. Although the North Hill targets are not expected to contain a large number of ounces, they would be very inexpensive to mine due to being at or near surface and to transport to an adjacent Phase II pad.

The Phase I area also contains better-than-average grades in the early years of the mine plan and has been drill tested to mostly oxidized Indicated categories with the potential to be quickly upgraded to Reserve Category with a Pre-feasibility study. Operational advantages for development of Wind Mountain include its location in a sparsely populated region of northwestern Nevada (less than a 2-hour drive from Reno), county-maintained roads, power lines to the property, location six miles from a geothermal power station, and no known environmental or archaeological impediments.

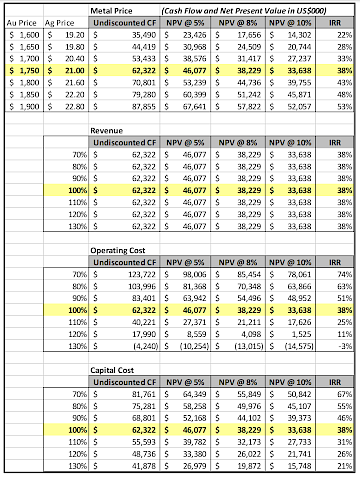

Sensitivity studies by RESPEC are presented in the table below. RESPEC notes that additional studies such as further metallurgical studies to evaluate crushing higher-grade portions of the deposit and grid drilling to delineate economic portions of the previously mined “waste rock”, which are given no value in the current model, could further enhance the economics. For example, RESPEC notes that 1.1million tons of historic mine waste is currently classified as “waste” and must be removed during Phase I mining; however, results of limited drilling, surface sampling, and trenching by Bravada suggest the material contains potentially recoverable gold. RESPEC and Woods recommends that the material be placed in a stockpile for additional study or utilized as over liner on the leach pads; the material potentially would be added to the currently designed Phase I pad to further reduce the strip ratio and increase positive economics.

RESPEC, Woods Process Services, and Debra Struhsacker, Bravada’s Environmental Permitting and Government Relations Consultant, compiled the technical report. Thomas Dyer, P.E. is a Principal Engineer for RESPEC and is responsible for sections of the technical report involving mine designs and the economic evaluation; Michael Lindholm, C.P.G., is a Principal Geologist for RESPEC, and is responsible for the sections involving the Mineral Resource estimate; Jeffery Woods, SME MMSA QP, is an independent Principal Consulting Metallurgist with Woods Process Services and is responsible for the sections on process 13, 17 and 21. The PEA relies on Debra Struhsacker as an expert in permitting. Thomas Dyer, Michael Lindholm and Jeffery Woods are the Qualified Persons of the technical report for the purpose of Canadian NI 43-101, Standards of Disclosure for Economic Analyses of Mineral Projects.